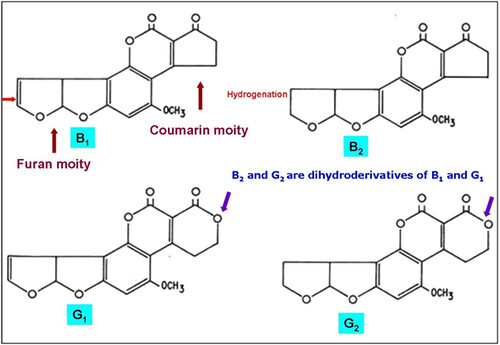

Aflatoxin contamination due to invasion by Aspergillus flavus (Fig.1) and A. parasiticus is a major problem in peanuts (also called groundnut). Aflatoxins are potent toxic, carcinogenic, mutagenic, immunosuppressive agents, produced as secondary metabolites by the fungus. Among 18 different types of aflatoxins identified, major members are aflatoxin B1, B2, G1 and G2 (Fig 2). Aflatoxin contamination although does not affect yield, but it causes serious health risks to human and cattle. Kumar et al. (2008) reviewed the commodity-wise etiology and contamination process of the major mycotoxins and the magnitude of contamination in commercially important agricultural commodities. The distribution of aflatoxins is very heterogeneous in a lot. Most of the aflatoxins in contaminated materials reside in only a small proportion of the kernels. If this substandard material could be separated and discarded the remaining high quality nuts will be virtually free from aflatoxins.

Fig. 1. Aspergillus flavus colonized kernel (Left) and the fungus in culture (Right)

Fig. 2. Structure of four aflatoxins

Contamination of peanuts with aflatoxin may occur despite the most strenuous efforts directed at prevention. However, a good potential for removing kernels contaminated with aflatoxins exists at the processing level when the peanut is blanched for value addition. On-site studies conducted at Directorate of Groundnut Research (formerly NRC for Groundnut), Junagadh, Gujarat in India, in association with some the peanut processing industries to know effectiveness of sequential sorting on removing aflatoxin contaminated kernels from bulk peanut (Kumar et al, 2010). Farmers’ stock of a Virginia bunch peanut cultivar, GG-20, presumably containing aflatoxins was passed through sequential processes of shelling, sizing and grading (mechanical and camera sorting), roasting, blanching, colour sorting (camera sorting followed by manual sorting) before value addition and packaging.

The results revealed that the sequential sorting process was effective in separating aflatoxin-contaminated kernels from bulk peanut lot (Table 1). The electronic eye sorting in conjunction with manual sorting resulted in reduction of aflatoxin content of bulk lot from approximately 200 ug kg-1 to <30 ug kg-1 in the good grade HPS peanut.

Table 1. Aflatoxin content of different grades of whole peanut isolated by sequential sorting

| Fractions | Percent of sample | Aflatoxin B1 * (µg kg-1) |

| Bulk peanut lot | 100 | 100.0-193.5 |

| Rejected by mechanical screening | 3.0 | 2166.0-3457.1 |

| Rejected by camera sorter | 15.4 | 40.0-74.1 |

| Rejected by manual sorting | 0.8 | 150.1-471.0 |

| Good grade HPS lot | 80.8 | 3.3-29.9 |

* Range of aflatoxin in 10 samples

Further, the data on aflatoxin content in the different grades of blanched kernels indicated that the highest level of aflatoxin (~ 1000 ug kg-1 ) was in the blanched kernels having large dark brown spots (Table 2). The typical discolouration of aflatoxin-affected kernels was easily discernible after blanching, even by the naked eye, by their typical dark brown spots (Fig.3). Blanched kernel with large dark brown spots had aflatoxin in the range of 879.74-1015.18 μg kg-1 while kernel with small dark brown spots had aflatoxin in the range of 4.97-40.08 ug kg-1 (Table 2). Thus the larger the size of discoloured spots higher was the aflatoxin level.

Table 2. Aflatoxin content in the different grades of sorted blanched peanuts

| Samples | Aflatoxin B1 (ug kg-1) | |

| Range* | Mean** | |

| Good grade HPS lot after blanching | 1.30-9.94 | 3.31 |

| Blanched kernels without spots | 0.00-0.68 | 0.33 |

| Blanched kernel with large dark brown spots | 879.74-1015.18 | 954.17 |

| Blanched kernel with small dark brown spots | 4.97-40.08 | 13.04 |

| Blanched kernels with burnt spots | 0.04-0.33 | 0.06 |

* Range of aflatoxin in 10 samples ** Mean of 10 samples taken from different lots (one sample from each lot)

Fig. 3. Blanched kernels: a. Kernels with burnt spots, b. Kernels affected by aflatoxins showing typical dark brown spots, c. Good grade

When the aflatoxin-affected kernels were split open the white mycelium with greenish sporulation of the A. flavus was visible in most of the kernels, but the same was absent in the kernels that developed burnt spots during roasting (Fig. 4).

Fig. 4. Blanched kernels split open: good (top 2 rows), aflatoxin affected (middle 2 rows), and kernels with burnt spots (bottom 2 rows)

The peanut industries involved in processing and value addition should invariably follow the sequential sorting procedures to ensure supply of aflatoxin free peanut to consumers.

References:

1. Kumar V, Basu MS and Rajendran TP (2008). Mycotoxin research and mycoflora in some commercially important agricultural commodities. Crop Protection 27: 891-905.

2. Kumar V, Bagwan NB, Koradia, VG and Padavi, RD (2010). Colour sorting - an effective tool to remove aflatoxin contaminated kernels in groundnut. Indian Phytopathology 63 (4): 449-451.

About Author / Additional Info:

Author is a Senior Scientist (Plant Pathology) working at ICAR-National Research Centre on Litchi, Muzaffarpur, Bihar (India). Currently working on diseases of litchi (Litchi chinensis), and mycorrhizal association in litchi. Formerly, he had worked on groundnut (aflatoxins and disease management) at ICAR- Directorate of Groundnut Research, Junagadh, Gujarat (India).