Advantages

Invert syrup obtained by this method is

· completely healthy and ecologically safe, particularly convenient for the production of children and dietary food;

· It does not crystallize, has a long shelf life in a liquid state and it can be easily transported in any weather conditions;

· It is colorless;

· The degree of inversion of 0-100% can be arranged depending on the buyer’s and consumer’s needs (contrary to the acid inversion where one cannot limit or control the percentage of inversion);

· The inverted final product contains no salt, nor hydroxymethylfurfural (HMF);

· It is sweeter than acid based invert, therefore it is lower in calories;

· There are no problems regarding purchasing raw materials, their storage and disposing of the packaging, as with inverted acids (hydrochloric acids);

· Less use of energy because the production process is run at 55ºC;

· Lower labor cost because the process can be easily automated;

· Savings when buying the sucrose are 40%;

· Last but not least, it is not affected by the ban of EU countries because it contains only 5mg/kg (or less) of HMF. The EU countries are planning the total ban in the production and import of inverted acids and HMF by the year 2017.

This method and the invert thus obtained can be a replacement for almost all kinds of sugar in food, pharmaceutical, and other industries.

DESCRIPTION OF NEEDED EQUIPMENT AND OBTAINING OF THE INVERT BY MEANS OF THE MIZONASA© PRODUCT AND MIZONASA© TECHNOLOGY

Most invert syrup producers have used the acid procedure in their production in their technological process i.e,. a powerful acid is added to the sucrose solution and is heated or boiled, thus causing harmful HMF, and then an alkaline solution is added to neutralize the acid thus causing the causing the formation of a harmful salt.

Therefore, we are offering the use of the MIZONASA© product and the transition to the MIZONASA© technology with possible adaptation of the existing technology, as well as the construction of new and inexpensive one.

The advantages of our product and technology are as follows:

1. The Advantages to the Producer

1.1. There are considerable savings to be made ( t he advantages over the acid procedure are set in bold and italic) :

a) MIZONASA© has a higher catalytic activity, so the obtained invert syrup is 30-40% sweeter than sucrose, which automatically mean less use of sugar;

b) The inversion with the use of MIZONASA© is performed at the temperature of 40-50%< oC, meaning lower energy consumption;

c) Invert syrup obtained by MIZONASA© does not crystallize during storage, which leads to further energy savings, and allowing easy transport of product, irrespective of the distance, outside temperature and weather conditions, in contrast to the acid procedure;

d) Lower labor cost – it is easy to automate the process, so there is no need to employ supervisory staff;

e) The equipment does not corrode during the processing meaning it will last longer and provide savings on capital equipment. It is possible to use plastic equipment instead of stainless steel;

f) Transportation and storage of strong acids and alkaline, and disposal of packaging are eliminated, thus saving on storage fees and space.

g) No hydrochloric acid (HCL) is used – therefore, no costs and risks connected to its purchase, storage and use, especially in relation to environmental protection;

h) The same goes for sodium hydroxide (NaOH).

1.2. Quality Aspect in Production:

a) It is possible to obtain the sugar invert with different degrees of inversion (if needed from 0-100%) depending on buyer needs, in contrast to the acid procedure where inversion degree does not exceed 70% and it cannot be stopped at the desired degree.

b) Product stability is such that, depending on producer needs, it can be limited to any quantity. It can be used constantly for months on end and shelf life can extend to several years in a 70% (or more) invert solution. It does not crystalize with practically unlimited shelf life provided it does not undergo a secondary pollution.

1.3. Ecological aspect :

a) By using the MIZONASA© product and technology there are no harmful residues released into the environment, because the production is completely eco-friendly and safe.

b) After special treatment, the used up the MIZONASA© portion can be converted to be utilized in filters to treat wastewater because it binds heavy metal ions.

2. Consumer Perspective

a) Healthier products are obtained without harmful furfurals and salts causing high blood pressure.

b) The products contain fewer calories but remain as sweet as honey. They are very popular in baby food production and are generally known as Dietary and LIGHT Products.

Potential Buyers:

1. Large confectionery (producers of sweets);

2. Soft and alcoholic drinks producers;

3. Syrup producers;

4. Small confectionery (pastry makers, bakers, honey makers…);

5. The pharmaceutical industry;

6. Tobacco industry;

7. Other industries…

BRIEF EXPLANATION OF THE PRODUCTION TECHNOLOGY

The solution of sucrose passes through a MIZONASA© tubular reactor. Caused by the MIZONASA© product, the sucrose molecule is split by a water molecule into equal (equimolar) amounts of glucose and fructose, thus obtaining the invert syrup. The degree of inversion (from 0 to 100%) is regulated by controlling contact time between the sugar solution and MIZONASA©.

The obtained syrup is colorless, it has improved organoleptic characteristics, honey characteristics (sweetness and viscosity), without additives, and is never prone to crystallization.

The Inverting of Sugar

The technological procedure at the beginning of the invert production is similar to that of the acid conversion. The initial procedure includes sampling and checking of quality of the input raw material – water solution of sucrose.

Previously prepared sugar solution (final concentration of 65-70%, according to what is specified in technological requirements) is released through the tube in which the MIZONASA© is located. The tube is a plastic or steel pipe, kept at the constant temperature at 55ºC by thermal coating, water or of some other method. When the sucrose solution goes through it, inversion occurs (sucrose converts into equimolar concentration of glucose and fructose). The degree of inversion is determined by the contact time of sucrose solution and the MIZONASA©. The procedure is happening fast, and it is implemented in order to obtain the required controlled inversion, degree up to 90% (100% inversion entails long contact time). A controlled inversion or inversion greater than 70% cannot be achieved in acid procedures, against which we are competing.

After inversion, the quality is checked in the laboratory (67% dry mass content increases to 70%, and the inversion level is superior to 80%). The product is either stored or used immediately. The production process is completely closed and uses only the purest food chemicals so there is no risk of spoiling the product. The invert with this concentration is not prone to microbiological contamination for a short period of time. For extremely long storage it is necessary that the dry mass percentage be around 72-80%. A pH of 4.5 also protects the product from contamination.

The Characteristics of Invert Obtained by the MIZONASA© Technology

The invert syrup is of pale yellow color, which comes from the dissolved sugar. There are no harmful components and it is healthier than glucose or high-fructose sweeteners. When compared to the traditional, acid procedure, there is no salt, no characteristic strong yellow color, and there is also no hydroxymethylfurfural (HMF), which is the main cause of the expected ban of the use of acid hydrolizates in confectionery and other industries. The acid method is absolutely not applicable in pharmaceutical industry.

Numerical example

A 67% sucrose solution has the density of 1.332g/cm3. 1l therefore weighs 1.332g. 1l is completely inverted if it passes through the tube whose MIZONASA© volume is 1l during 1 hour, according to the described conditions (pH 4.5 and t=55ºC). So, in 24 hours the tube processes 24x1.332kg (≈32kg) of invert syrup, with 80% inversion. Since this is a continual process during 30 days, the tube yields 32x30=960kg of 80% invert per 1l of MIZONASA©. The version of a tube has the suggested volume capacity for 10l of MIZONASA© (15l physical capacity). This tube produces 9.6 tonnes of inverted sugar syrup per 1 month.

Briefly, 1 tonne of MIZONASA© each day makes 32 tonnes of invert syrup. Even better results are expected upon improving MIZONASA©.

The main argument for invert production by using MIZONASA© product and MIZONASA© technology is that with the increase in quantity, the production costs per unit mass are further reduced. Larger quantities of invert could substitute crystal sugar in numerous recipes, where glucose or maltose syrup is used. Therefore, we hope this argument is what is needed to be convinced about the production and use of invert syrup obtained by the MIZONASA© technique.

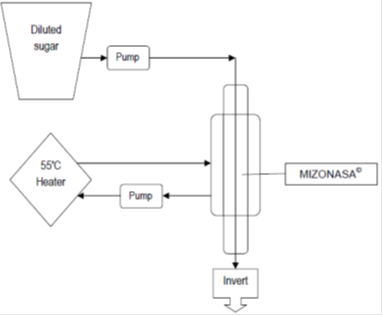

The chart flow is given below:

The picture shows the equipment to obtain the invert syrup, by using the MIZONASA©

With minor modifications to the acid-method equipment, any existing producer can produce invert syrups with MIZONASA© technology. A filter made of stainless steel or plastic in which MIZONASA© product is introduced, has to be added (schematically: the top of long capsule, right). Dissolved sugar is then placed over the product, adhering to the prescribed contact time and the desired invert is obtained.

About Author / Additional Info:

I’m a University Lecturer, UN Senior Reviser, Barclays International Funds Broker, The British Council scholar. I’ve been running a small firm providing investment research as well stock trading for private clients.

LinkedIn profile: https://www.linkedin.com/in/adventurem?trk=nav_responsive_tab_profile