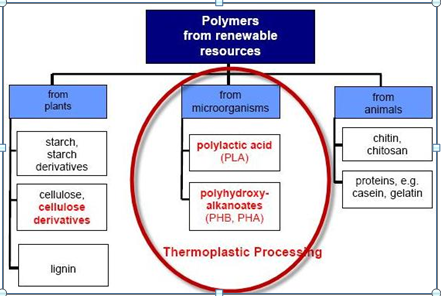

Image Source: http://making-biodiesel-books.com/wp-content/uploads/2012/02/bioplastics.jpg

What are biodegradable bioplastics?

Biodegradable bioplastic is a form of plastic derived from renewable biomass that can be broken

down in the environment by micro-organisms (Mooney, 2009). These are categorized into four classes.

1. Starch-based bioplastics can be made from either raw or modified starch (e.g. thermoplastic starch or TPS) or from the fermentation of starch-derived sugars (e.g. polylactic acid or PLA). Maize, wheat, potatoes and cassava are the examples of common starch sources.

2. Cellulose-based bioplastics are basically chemically-modified plant cellulose materials such as cellulose acetate (CA). Examples of cellulose sources are wood pulp, hemp and cotton.

3. Lignin-based bioplastics- mainly contain lignocellulosic plant material produced as a byproduct of the paper milling industry.

4. Plant proteins such as maize ‘zein’ can can also be used for synthesis of bioplastics.

What are non-biodegradable bioplastics?

These are a form of plastic derived from renewable biomass that cannot be easily broken down in the environment by micro-organisms. These are categorized into two types.

Conventional plastic resins- can be derived from plant oils and are synthesized using compounds extracted from castor, soya bean or oilseed rape oil. Examples- polyurethane (PU) produced from soya bean oil and nylon (polyamides or PAs) made using castor bean oil.

Conventional polyethylene (PE)- can be manufactured from bioethanol.

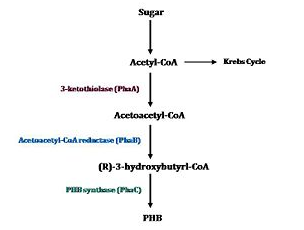

Polyhydroxybutyrate- A biodegradable plastic substrate

Polyhydroxybutyrate (PHB) is synthesized from acetyl-CoA which used as precursor. These are used for the synthesis of biodegradable plastics with thermoplastic properties. At present, these are produced by bacterial fermentation but the cost of this plastic is substantially higher than that of synthetic plastics. To overcome this problem attempts are being made to produce PHAs in transgenic plants to reduce the cost. Genes encoding the two enzymes, aceto-acetyl-CoA reductase (phb B) and PHB synthase (phbC), and the gene phbA, which are involved in the PHB synthesis, have been identified from Ralstonia eutropha. These genes have been transferred and expressed into Arabidopsis thaliana (Mooney, 2009). These are receiving commercial interest as a promising candidate for the production of biodegradable thermopalstics due to the role played by them.

Image Source: http://2008.igem.org/wiki/images/thumb/6/6d/PHBpathway.jpg/300px PHB pathway.jpg

Applications of Bioplastics:

More than half of bioplastics are currently used in various areas viz., in packaging applications such as bottles, film, and loosefill. These are also used in waste collection bags, carrier bags, mulch-film and food serviceware. Along with packaging applications, bioplastics are currently used in automotive parts and electronics housings.

Starch-based bioplastics (eg. TPS) have been used to manufacture food serviceware and also for carrier bags. Polylactic acid which is a starch based sugar fermentation product is mainly used in cold drinks cups and bottles, food packaging film and containers, carpets and clothing. PLA can also be used to manufacture CDs and electronics casings.

Cellulose acetate films are used in food and consumer goods packaging.

Lignin-based bioplastics are also having applications in electronics housings and golf tees.

References:

1. http://en.european-bioplastics.org/wp-content/uploads/2011/04/fs/Bioplastics_eng.pdf

2. Mooney, B. P. 2009. The second green revolution? Production of plant-based biodegradable plastics. Biochem. J, 418, 219â€"232.

About Author / Additional Info:

I am currently pursuing Ph. D in Environmental science