Authors: Sanchita Ghosh, RatnaPriyanka R

Ph.D Scholar, Department of Floriculture and Landscaping, HC&RI, TNAU, Coimbatore

Corresponding author: sanchitajolly28@gmail.com

What is dry flower technology?

Fresh flowers and foliages are perishable and delicate in nature and cannot retain their beauty and fresh look for long period of time. Moreover non availability of fresh flowers and foliages throughout the year creates great hindrance. Drying of flowers is a method of preservation of flowers or the method of removing moisture from the flowers. Dry flowers constitute more than two-thirds of the total floriculture exports. Dry flowers can be used to prepare value added products like greetings card, floral balls, wall hangings etc. The demand for dry flowers is increasing at an impressive rate of 8-10 per cent annually thus offering a lot of opportunities for the Indian entrepreneurs to enter in the global floricultural trade. The range of dried flowers and other attractive plant parts is quite extensive, namely stems, roots, shoots, buds, flowers, inflorescences, fruits, fruiting shoots, cones, seeds, foliage, bracts, thorns, barks, etc. A number of flowers respond well to drying techniques such as anemone, zinnia, sweet william, carnation, stock, freesia, narcissus, chrysanthemum, pansy, daffodils, marigold, rose, lilies etc and foliage like ferns, aspidistra, eucalyptus, ivy, laurel, magnolia. This industry is labour intensive and can generate ample job opportunities to thousands of unemployed men and women.

Scope

The dried flower industry in India is about 40 yrs old, and its product have got high export value. India exports 60-70 % of dry flowers. Export of dried flowers and plant part is about Rs. 100 crore per year. Share of export is less than 1% of the world requirement. Main export markets are USA, the Netherlands, UK and Germany. Major dry flower industries units are located in Tuticorin (TN), Kolkata, Maharashtra, Karnataka and A.P in India. This industry provides direct employment to around 15,000 persons and indirect employment to around 60,000 persons.

Techniques of flower drying

Sun drying

Sun drying is easy and cheap method. It uses solar energy and requires large amount of space. The plants are damaged by exposure to adverse environmental condition. No drying equipment is required. The flowers are hanged upside down in ropes or in bamboo splits. Examples- Delphinium, celosia etc.

Air drying

The air drying is a very common method of drying where plant materials are attached to rope/wire and are kept in hanging position either in dark or in the sun for quick drying. Air drying requires a warm clean dark and well ventilated area with low humidity. Darkness helps preserve the flower colour and flowers take 1-3 weeks to dry completely. Examples-celosia, amaranth, sunflower, calendula, gomphrena, larkspur

Press drying

In press drying, the flowers and foliage are placed between the folds of newspaper sheets or blotting papers giving some space among flowers. These sheets are kept one above the other and corrugated boards of the same size are placed in between the folded sheets so as to allow the water vapour to escape. Time required for press drying varies with flower crops of different flower crops and they concluded that rose, carnation and helichrysum required 120, 132 and 72 hours, respectively, for press drying.

Embedded drying

Sand, borax, silica gel, sawdust, perlite and combination of these are usedas media for embedding. The material should be very fine and size should be 0.02 to 0.2 mm. Among these, sand and borax are cheaper but they take more time for drying. For delicate flowers like roses, dahlia, carnation etc, silica gel is ideal drying agent. Examples: rose, aster, carnation, marigold, dahlia, larkspur, geranium, zinnia, chrysanthemum and delphinium

Oven drying

Now a days hot air and microwave ovens are also being used for faster drying and to improve the quality of dry flowers. In these methods, plant material is kept at controlled temperature for a specified time typical of the plant species. Candytuft, chrysanthemum, doembeya, gerbera, gomphrena, helichrysum require 48 hours in 45-490C. While china aster, zinnia, rose require 40-44 0C for 48 hours.

Microwave oven drying

The principle of oven drying is liberating moisture by agitating water molecules in the organic substances with the help o electronically produced microwaves. Embedded flowers and foliages in silica gel contained in a non-metallic earthenware or glassware are kept in oven for few minutes .The material after taking out from microwave oven is kept outside in dry atmosphere for a specific time for setting. The setting time varies from material to material. The time required for dehydration in microwave oven varies from 1- 4 minutes and setting time 2-5 hours. Antirrhinum, carnation, china aster chrysanthemum gerbera, gladiolus require 3 min in microwave oven.

Glycerine drying

Glycerine drying has been used by several workers especially to preserve foliage. Many types of foliage have been successfully preserved by either immersing leaves or placing crushed stems in a 33 per cent glycerol solution. The resultant leaves are soft and flexible. This method is found more suitable for eucalyptus, hydrangea, ivy and magnolia. Drying time varies from 4 days to 2 weeks.

Freeze drying

The most effective method of flower preservation is freeze drying. Freeze drying relies on the principle of sublimation. In this process, the flowers are placed into a refrigerated chamber and the temperature of the chamber is lowered below freezing. A vacuum is then created in the chamber, causing the moisture in the flowers to sublimate, or change from solid to gaseous form. The water vapor is then collected in a separate chamber and the dried flowers are allowed to slowly warm to room temperature.

Cryo drying

Several cultivars of carnation flowers can be successfully cryo dried and remained naturalistic in appearance softer being placed in -800C for 12 hours and then placed in freeze drier for 7 days. After receiving fully opened flowers from the field they are cut into 15 cm length and placed in vials so that the basal 5 cm were immersed in the solutions of glycerin, clove oil, DMSO, and wetting agent. After the pre treatment the flowers are kept at -800C for 12 hours.

Skeletonization of leaves

Skeleton leaves are semi-transparent leaves also called as fossil leaves. Skeleton leaves are prepared by placing selected leaves in a pot with equal amount of bicarbonate and baking powder. Water is added in the pot boiled and stirred gently on a low flame. Once leaves have softened the chlorophyll is rubbed off gently. Then the leaves are bleached and dried on paper towel. Skeleton peepul leaf is mounted on various objects like handmade paper, wedding cards etc to give elegant look.

Care of dried products

Since dried flowers are very brittle and fragile, they are to be handled gently and carefully. They absorb moisture and lose shape so they should be stored in moisture proof container. For storage Floral Box, Glass desiccators, Tin Box, Cartons wrapped with plastic sheet or wax paper are used. Small quantity of silica gel may be placed at bottom to absorb moisture. Material should be protected from direct sunlight, place in dark, warm, well ventilated area.

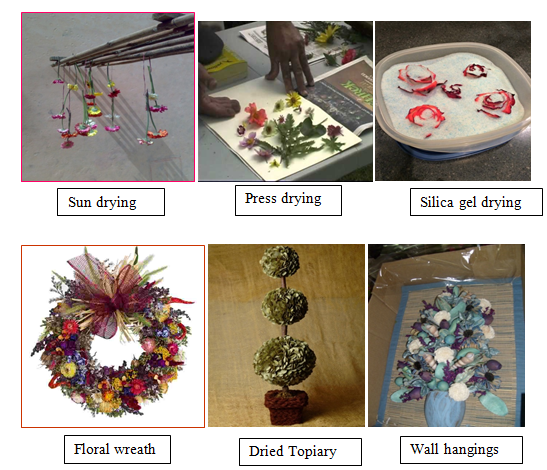

Fig. Methods of flower drying and value added product of flowers

About Author / Additional Info: