Authors: Satish Kumara , Ajay Kumarb , Aman Jaiswalb , Deepak Kumar Kolib

aDivision of Seed Science & Technology, ICAR-Indian Agricultural Research Institute, New Delhi (India) 110 012

bDivision of Microbiology, ICAR-Indian Agricultural Research Institute, New Delhi (India) 110 012

Seed is a living product and must be grown, harvested and processed correctly to maximize its viability and subsequent crop productivity. Seed quality has a profound effect on the development and yield of a crop. Good seed quality can increase yield significantly. Seed quality depends on the health, physiology, germination ability and physical attributes of seeds, including the presence or absence of disease, insect infestation, and the presence or absence of weed seeds or other plant varieties. Rapid, simple and accurate detection techniques must be developed for farmers and the agro-industry to ensure quality seed during seeding, growth, harvesting, storage and transport to consumers. The sowing quality of seed is associated with the germination and growth conditions after sowing and depends on seed composition, kernel maturity, insect infestation, diseases, cleanliness and germination ability. The genetic purity of seeds may be detected by molecular identification, DNA analysis, isotope fingerprinting and mineral element analysis. Protein electrophoresis, gas chromatography, high performance liquid chromatography, tetrazolium tests, accelerated ageing and conductivity tests have been employed to evaluate the vigour and germination quality of seeds. Most of these chemical and physical techniques exhibit high accuracy and good reliability but have certain limitations, such as their high cost, long time requirements and high operator requirements. With the increasing demand for rapid, non-destructive and reliable techniques for evaluation of seed quality in the modern agro-industry, high performance techniques must be developed for the evaluation of seed quality. A number of non-destructive testing technologies have been developed for evaluation of seed quality. Non- destructive testing technologies are rapid, accurate, reliable and simple methods for assessing the quality of seeds, machine vision, spectroscopy, hyper spectral imaging, electronic nose, soft X ray imaging and thermal imaging techniques.

History

- First color seed sorter machine developed by- ‘SATAKE’ seed company (1932)

- First indigenous multi-channel color seed sorter machine- Peanut and Rice industry in India (1970)

- Intel Seed Ltd. developed modern color seed sorter (2015), uses high resolution camera and high speed imaging software.

Non-destructive methods of seed quality assessment

Machine Vision

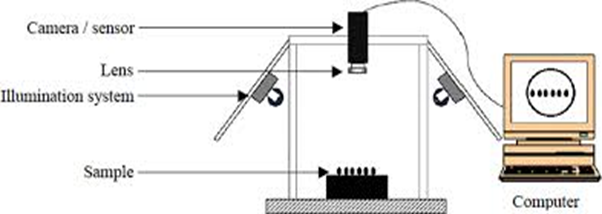

Machine vision, also known as ‘computer vision’ or ‘computer image processing’, is an artificial intelligence technique that simulates human vision. This technique is non-destructive, reliable and rapid and has been proven to be an effective and powerful technique for quality evaluation of food and agricultural products, particularly seeds. A typical machine vision system consists of four basic components: an illumination system, a sensor or camera, a lens and a computer with frame grabber/digitizer. Most applications of machine vision address the visible spectrum (380–780 nm). A machine vision system should be capable of identifying and grading seeds based on image external features, such as size, shape, color and texture.

Spectroscopy

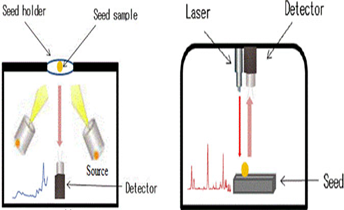

Spectroscopy is used to investigate and measure the spectra produced when matter interacts with, or emits, electromagnetic radiation. A range of spectroscopic techniques, such as near-infrared- (NIR), mid-infrared- (MIR), fluorescence-, Fourier transform infrared (FT-IR) and Raman spectroscopy have been widely and successfully used as sensitive and fast analytical techniques for authentication and quality analysis of a variety of agricultural seeds. NIR and MIR spectroscopy are based on molecular overtones and combined vibrations. FT-IR spectroscopy is a technique used to record infrared spectra and detect radiation in the MIR region. FT-IR spectroscopy is an information-rich analytical technique, as it provides a greater amount of chemical information regarding the scanned sample than NIR spectroscopy.

Hyper -spectral imaging technology

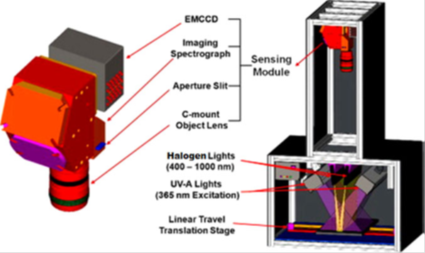

Hyper spectral imaging has recently emerged as a powerful analytical technique for food quality and authenticity analysis. This technique is used to acquire both spectral and spatial information from an object. A hyper spectral imaging system includes light sources, wavelength dispersion devices and detectors. As the centre of a hyper spectral imaging system, wavelength dispersion devices are used to disperse broadband light into different wavelengths. The detector collects light, which carries useful information from the wavelength dispersion device and measures the intensity of the light by converting radiation energy into electrical signals. Using hyper spectral imaging, sample analysis is convenient and comparatively fast because a large number of samples are analysed at the same time, whereas spectroscopic methods analyse only one sample at a time. Machine vision and spectroscopy can only provide spatial or spectral information, whereas hyper spectral imaging, which integrates machine vision and spectroscopy advantages, can simultaneously obtain spatial and spectral information by using only one system. In this regard, hyper spectral imaging has been widely used by researchers to evaluate the exterior quality of seeds and predict their internal composition.

Thermal imaging

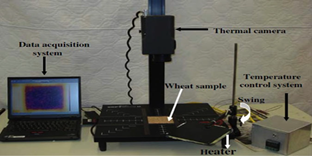

Thermal imaging is a technique for converting the invisible radiation pattern of an object into visible images for feature extraction and analysis without establishing contact with the object. Using this method, the surface temperature of any object can be mapped at a high resolution in two dimensions. The thermal data produced may be used directly or indirectly in many ways. The application of thermal imaging has gained popularity in the agro-food industry in recent years. The major advantage of thermal imaging is that it is a non-contact, non-invasive and rapid technique that can be used in online applications. Thermal cameras are easy to handle and highly accurate temperature measurements are possible. Using thermal imaging, it is possible to obtain temperature mapping of any particular region of interest with fast response times, which is not possible with thermocouples or other temperature sensors that can only measure spot data. In addition, thermal imaging does not require an illumination source, unlike other imaging systems. Nowadays, thermal imaging has a potential application in many operations involved in agriculture, starting from assessing seed quality, especially in detection of diseases, insects and seedling viability, estimating soil water status, estimating crop water stress, scheduling irrigation, determining disease and pathogen affected plants, estimating fruit yield and evaluating maturity of fruits and vegetables.

Soft X-ray imaging

Electromagnetic waves with wavelengths ranging from 1 to 100 nm (and energies of approximately 0.12 to 12 keV) are called soft X-rays. The low penetration power of these waves and their ability to reveal internal density changes make soft X-rays suitable for use in evaluating agricultural products. Soft X-ray imaging is a well-known technique that takes a few seconds (3–5 s) to produce an X-ray image. Soft X-ray imaging has begun to be used in the seed industry to detect internal voids, defects, insect infestation and insect damage.

Electronic nose

An electronic nose is an instrument consisting of an array of electronic and chemical sensors with partial specificity and a pattern recognition system that is capable recognizing simple or complex odours. These devices typically have arrays of sensors used to detect and distinguish odours precisely in complex samples and at low cost. Electronic nose devices have been employed in a wide variety of applications, including classification of kernels and microbial pathogen detection.

Applications

Quality assessment of seeds: Insect damage and diseases

Seed damage by insects, fungi or natural causes, such as germination, are an important factor in seed quality during storage and processing. Seed damage is therefore taken seriously by consumers and the food industry. Non-destructive techniques such as machine vision, spectroscopy, hyper spectral imaging, soft X-ray imaging, electronic nose and thermal imaging have been widely used in the detection of insect damage, insect infestation and diseases in seeds. Machine vision has been used together with back-propagation neural networks based on colour features to detect external defects in rice seeds, such as germs, diseases and incompletely closed glumes, with an accuracy of 98.6–99.2%. Hyper spectral imaging has been used to detect sprout damage in wheat and to detect sprouting barley. Spectroscopy-based methods have also been used to detect and classify fungus-infected maize wheat and soybeans to determine the percentage of fungal infection in rice and to identify the green mottle mosaic virus in cucumber.

Quality assessment of seeds: Variety identification and classification

Variety identification and classification of seed species using non-destructive techniques has been extensively investigated by researchers worldwide. Machine vision has been used to identify four wheat varieties using morphological features and colour features with an accuracy of 95.86%, which suggests that morphological features are more effective than colour features in recognizing wheat varieties. Electronic nose is used to distinguish among varieties of wheat seeds with an accuracy of 100%. Thermal imaging was used in a recent study to identify eight western Canadian wheat varieties. The overall classification accuracies of eight-class model, red-class model (four classes), white-class model (four classes), and pairwise (two-class) model comparisons obtained using a quadratic discriminant method were 76, 87, 79 and 95%, respectively. Hyper spectral imaging systems have been used for accurate and reliable discrimination among varieties of maize seeds for classification of four varieties of maize seeds in different years for identification of wheat varieties, for differentiation of wheat classes grown in western Canada and for differentiation among varieties of rice.

Quality assessment of seeds: Seed viability

A good-quality seed is one that is capable of germination under various conditions. A non-viable seed is one that fails to germinate even under optimal conditions. Non-destructive techniques, mainly spectroscopy and hyper spectral imaging, have been widely used to predict seed viability. A machine vision system was used to predict alfalfa and sativa seed germination ability using the RGB (red, green, blue) density value with correlation coefficients of 0.982 and 0.984 for alfalfa and sativa, respectively.

Researchers have also studied soybean and snap bean seed germination ability using electric impedance spectroscopy in the frequency range of 60 Hz to 8 MHz. Spectroscopy has been used to distinguish viable gourd, cucumber, patula pine and watermelon and pepper seeds from their non-viable counterparts, to assess corn seed viability. Hyper spectral imaging systems have also been used for accurate and reliable discrimination of viable and non-viable seeds of corn, radish, watermelon and pepper with accuracies of 95.6, 95, 84.2 and 99.4%, respectively. Recently, a hyper spectral fluorescence imaging technique was used to extract the fluorescence spectra of cucumber seeds in the 425–700 nm range to discriminate between viable and nonviable cucumber seeds using four types of algorithms.

Advantages-Disadvantages of Non-destructive techniques

Advantages :

- Rapid

- Seed not damaged

- High accuracy

- Less chances of human error

- No Bio-chemical changes in seed

- High initial cost

- Require more technical skill to use instrument

- Some kind of seed sensitive to X-Rays are not suitable for testing

- Maheshwari, Chetna V., Jain, Kavindra R., and Modi, Chintan K (2012). Non-destructive quality analysis of Indian Gujarat-17Oryza sativa sp. indica (Rice) using image processing. International Journal of Computer Engineering Science Volume 2 Issue 3

- Olesen M H, Nikneshan P, Shrestha S (2015) Viability prediction of Ricinus communis L. seeds using multispectral imaging. Sensors, 15, 4592-4604.

- T. Repo, Paine, D.H., Taylor, A.G., (2002). Electrical impedence spectroscopy in relation to seed viability and moisture content in snap bean. Seed Science Research, 12, 17-29

- Shrestha S, Deleuran L.C., Gilsum, R., (2016). Classification of different tomato seed cultivars by multispectral visible-near infrared spectroscopy and chemometrics. Journal of Spectral Imaging, 5 a1

- Vresak M, Halkjaer Olesen M, Gislum R, Bavec F., Ravn Jorgensen,J (2016). The use of Image-spectroscopy technology as a diagnostic method for seed health testing and variety identification. PLoS ONE 11(3): e015201

References

About Author / Additional Info:

I am pursuing MSc in department of Seed Science & Technology from Indian Agricultural Research Institute, New Delhi-110012