Author: Shailza

Flowers are the wonderful creation of nature and regarded as symbol of love, beauty and paradigm of life. Besides their aesthetic value, flowers also play important role in improving the environment in addition to their economical and medicinal properties. Fresh flower production under open and protected conditions is predominant in floriculture industry. The fresh flowers, though exquisite in their beauty, but are expensive, short lived, sensitive to temperature and are available only during a particular season. Their freshness and beauty is lost due to various biochemical changes and microbial activities, thus, can be retained only for few days even by using the best techniques of post-harvest management. From studies it is observed that the shelf life of flowers could be prolonged only to an extent of 40% even when the best flower preservatives or chemicals are used. So, the alternative to this problem is DRY FLOWERS.

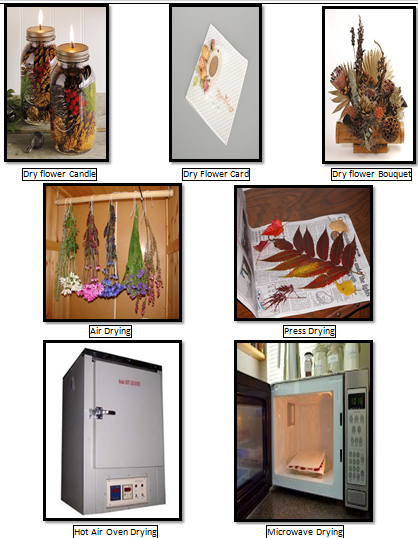

The dried or dehydrated flowers or plant parts are natural, comparatively inexpensive and have everlasting value with year around availability without disturbing their colour and form. The flower drying techniques involve reducing moisture content of flowers to a point at which biochemical changes are minimized while maintaining cell structure, pigment level and flower shape. Dry flower industry in India is more than 40 years old mainly due to its high export value. Dry flowers were introduced initially by the British in Calcutta due to its nearness to north-east and eastern regions where exotic and diverse blooms were available in nature. Dry flowers are essential export items both in national and international markets. Indian export of flowers is composed of 77% dry flowers exported mainly to USA, Japan, Australia, Russia and Europe. Exporting companies at Kolkata in West Bengal, Tuticorin in Tamil Nadu, Mumbai in Maharashtra and Hyderabad in Andhra Pradesh are earning 10-15 times higher returns than domestic markets. Different decorative floral craft items like cards, floral segments, wall hangings, landscapes, calendars, potpourris etc. could be made by using these dried flowers or foliages. This industry is labour-intensive and generate ample job opportunities to thousands of unemployed men and women. Thus, there is large potential to develop the dry flower industry to provide employment mainly to house wives and rural women.

Methods of drying or dehydration

Several methods are practised for drying or dehydration of different plant parts. It includes;

- Air Drying: It is an inexpensive method of drying also referred as ‘Upside Down’ or ‘Hang and Dry’ method of drying. Flowers of good quality and at slightly immature stage should be selected for drying. Firstly, the flowers are tied in bunches and hang inverted. Air drying requires a warm, clean, dark and well ventilated area with low humidity. This method takes 1-2 weeks for drying depending upon the moisture content, temperature and humidity. Flowers with crisp texture such asAcroclinium, Anaphalis, Helichrysum, Delphinium, Oregano, Rumex, etc. are suitable for drying with this method.

- Press Drying: This is one of the common, easy and inexpensive method of drying. In this method, specimen is kept in folds of newspaper, blotting paper or old notebooks etc, and then a heavy object is placed on the top. Time required for pressing varies with type of flowers and water content of tissue; however, it should be completed within 4 weeks. This drying time could be reduced if flowers folded in the sheets are put in oven at an appropriate temperature. Plant materials suitable for pressing are Candytuft, Chrysanthemum, Pansy, Rose, Daisy, Phlox, Statice, Zinnia, Ferns, Silver Oak, Thuja, Cockscomb etc

- Hot air oven drying: Temperature plays an important role in drying of flowers and other plant parts and in hot air oven, specimens are kept at controlled temperature conditions for a specified period of time. Drying in hot air oven or microwave takes less time as compared to the other methods such as air drying, water drying etc, however, the duration and drying temperature varies with plant size, structure, moisture content and stage of harvesting of the material. Usually the temperature of 40-50°C temperature is optimum for drying in hot air oven. Plant material for drying in hot air oven and microwave should be embedded in desiccants otherwise shrinkage is observed in dried material. Plant materials suitable for hot air oven drying are Paper flower, Gerbera, , Chrysanthemum, China Aster etc.

- Microwave drying: This is the quickest method of drying which generates little amount of heat also. It is based on the principle of liberating moisture by agitating water molecules in the organic substances with the help of electronically produced microwaves Microwave oven dried flowers looked fresh and more colourful than obtained by any other method. Drying in microwave takes only 5-10 minutes for drying. Containers with flowers after taking out from microwave should be kept for a particular period of time at room temperature so that the moisture evaporates and the plant material is fully dried. This is called ‘setting time’ which varies from species to species. This method of drying is best for flowers with many petals like Marigold, Rose, Carnation Zinnia etc.

- Embedded drying: Embedded drying is useful for delicate flowers with high moisture content that shatter or misshapen when air dried. This method of drying is usually preferred over air or oven drying as it reduces the problem of petal shrinkage. In embedded drying, the water content of the flower is completely absorbed by the surrounding desiccant material. The commonly used desiccants are silica gel, borax, corn meal, etc., which remove moisture from the flowers more rapidly than air-drying besides retaining the flowers in their natural form. Fine white sand found on the seashore (river sand) can be used for embedding because of its easy handling and availability. Silica gel is the best desiccant for getting excellent quality of dry flowers that retain colour and shape. Since, it does not cause bleaching shrinkage or brittleness to flower petals even if embedded for a long time. It is granular in shape and called as gel because it is a xerogel of silicic acid. Silica gel (60-120 mesh) is the best absorbent for removing moisture from flowers. Rose, Aster, Carnation, Marigold, Dahlia, etc. are suitable for drying through embedding technique.

- Glycerine preservation: Ornamental plant parts are generally preserved by treatment with ‘humectants’. ‘Humectants’ are hygroscopic chemicals, which help to maintain the suppleness of dried plant material by attracting water vapour from the surrounding atmosphere. Thus, the preserved plant material is less brittle than dried material, making it less prone to shattering and mechanical damage. The difference in preservation and other methods of drying is that the treated parts are actually preserved and not completely dried. Different humectants are used for preserving plant parts such as glycerine, polyethylene glycol etc. but, most commonly used is glycerine. 1 part of glycerine mixed with 2 parts of hot water is ideal mixture for dehydration. The duration of treatment varies from 2 to 6 weeks depending upon the texture and the size of the leaves and branches. Plant materials are not allowed to stand in the solution for longer time as it results in glycerine bleeding. Plant materials suitable for glycerinization are Anthurium, Aspidistra, Lemon, Eucalyptus etc.

Conclusion: The dried or dehydrated plant parts are natural, comparatively inexpensive and have everlasting value with year around availability without disturbing their colour and form. Not every method is suitable for drying each and every flowers or plant parts Because the material selected for drying is method specific and should be dried with appropriate technique otherwise, it will affects the quality of dried material.

Dry flower industry is labour-intensive and generate ample job opportunities to thousands of unemployed men and women but, this can only be happen if different trainings related to methods of flower drying and their value addition is provided to unemployed men and women especially rural housewives. Thus, there is need to focus on this important aspect of floriculture industry so that it can not only increase the total export of floriculture products from India but also it may help in providing employment to rural people also.

Value added products of dry flowers and methods of flower drying:

Image Source : Google

References:

1. http://hgic.clemson.edu/factsheets/hgic 1151.htm/

2. Dried and preserved ornamental plant material: not new but often overlooked and underrated. Acta Horticulture 454: 133-145, 1998- By D.C. Joycee.

3. http://www.muextension.missoure.edu/explor/agguides/hort/go6540.html/.

About Author / Additional Info:

I am currently pursuing Ph.D in Floriculture and Landscaping from Punjab Agricultural University, Ludhiana.