Authors: Er. Yogesh Kalnar1, Dr. Sandeep Mann2, Dr. Renu Balakrishnan3, Dr. Rahul Kumar4

1,2,3 Transfer of Technology Division, 4 AS & EC Division ICAR-CIPHET, Ludhiana

The food processing industry occupies a unique position in the Indian economy in terms of its potential for employment generation, increasing the farmers’ income and export growth. The establishment of Agro-Processing Centre is the present need in the production area for processing the agricultural produce, which would improve farmer’s income and livelihood in a sustainable manner. The present practice followed by farmers is the quick sell after harvesting of the agricultural produce without any processing and value addition, which would result imbalance between demand and supply and farmers will get lower prices in the market. With the help of APC farmer can add value to his produce and increase storage life with the help of machines which is easily available in the market. Farmers can process cereals, pulses, oilseeds and spices. For example farmer can make value added products out of paddy (rice) like milled raw and parboiled rice, flour and flakes and puffed rice, from wheat: wheat flour, Maida, Suji, dalia and noodles, from maize: maize flour and flakes, starch and puffed corns, from sorghum: sorghum flour, flakes and puffed sorghum from oilseeds: oil and cake; from Pulses: dal, besan, feed (husk and broken pieces) and roasted snack foods can be prepared and marketed easily.

What is Agro-Processing Centre (APC)?

Agro-Processing Centre is a place or subset of manufacturing where all the facilities required for pretreatment, processing, drying, packaging, storage and marketing (optional) are available in sequential manner for the raw materials and intermediate products derived from the agricultural sector. Agro-processing Centre comprises sectors in food processing such as fruits & vegetables, cereal/other consumer food products, rice milling, flour milling, pulse processing, spices grinding, oilseeds processing and such other agro-horticultural sectors. Agro-Processing Centre may be of an individual, community or cooperative enterprise. The APC creates additional value to a product so as to increase marketability of surplus produce available in the village, cluster of villages or surrounding locality. Processed and packed food products are prepared and marketed with specific brand name.

Importance of Agro-Processing Centre

Food processing has the main objective of providing a safe nutritious food in order to maintain health aspects and particularly the income generation for the producer and vendor. Food has been treated and packed since the earliest eras of man's history on earth. Herbs were dried and kept for use as remedies. Fermented beverages were made from fruits and cereals. Meat and fish were salted, smoked and dried. In the early days of food processing the main aim was safeguarding and preservation to maintain a supply of wholesome, nutritious food during the slack periods of year.

At the present time any type of crop is grown all over the world in protected cultivation and some appropriate agricultural practices. Nowadays consumers are more health conscious, and they know more about the products and their importance due to increased use of social media in day to day life. This lead to a demand for non-traditional foods those are not appropriate to the local environment. They need distinctive processing and packaging to protect them for their required storage life and this can be achieved by means of an APC.

The increasing number of women entrepreneur who now work away from home in small scale business by means of self-help groups (SHG’s), farmer producer organization (FPO’s) adds additional pressure for venturing into agro processing. Government also pushing agro processing sector by providing financial schemes and motivating the rural youths come forward in agribusiness sectors, also organizing the programs for doubling the farmer income by 2022.To meet these targets of doubling farmers income farmers have to be started their own food processing centers at their own field. APC can connect the gap between producer and consumer by ensuring the readiness of food products at proper time and at low cost. Moreover, the APC would create a market demand for fresh food grains which induce the farmer to produce surplus to earn more money. The Agro-Processing Centre is a major source of employment, it adds value to crops by processing, in some cases, by export, earns valuable foreign exchange, provides opportunities for import substitution and benefits a large number of farmers, packaging suppliers and vendors.

Layout of Agro Processing Centre

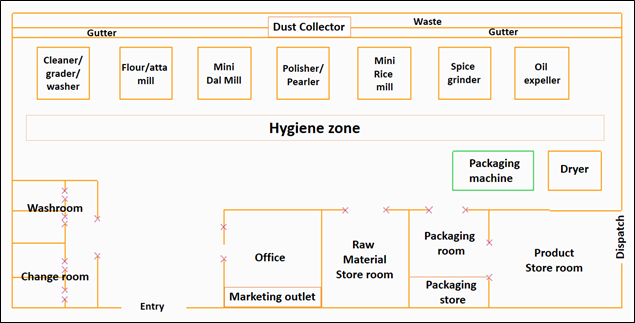

Fig.1 Prototype layout of Agro Processing Centre

Location and Building for Agro-Processing Centre: Before deciding plant location different factors should be analyzed. The plot should be of adequate size for both present needs and future development. The plant should be close to public transport such as rail or road. Access to electricity, water, and steam is essential. Waste disposal should be considered while planning the plant location. The owner should coordinate all the works with local competent authorities in order to avoid problems in the future. The choice of plant location should also take into account the neighboring surroundings: for example, location near to a waste dump could lead to microbiological contamination caused by birds. Drains must be located appropriately in all processing areas. Slope must be adequate to ease the flow of waste material/water. A well designed building should comprise sufficient space for work to be conducted out under adequate hygienic conditions, an area for machinery, equipment and storage, separation of operations that might contaminate food, adequate natural or artificial lighting, ventilation, and protection against pests. There are many technical regulations concerning construction of buildings and processing halls; e.g., outside walls, windows and doors should be constructed such that they are water, insect-and rodent-proof. The inside walls of the building should be painted white or other light color and their surface should be smooth, fall-safe, corrosion- proof and easy to clean. Floors should be resistant to spillage of products, water and disinfectants. They should be slip-proof and maintain their color. Experience shows that selection and preparation of the floor is one of the most difficult tasks facing the designer. The work areas have to be in adequate size to enable hygienic processing and plant cleaning. Plants and machines must not be positioned against the wall, for example if there is a risk of the wall- side becoming dirty. The arrangement of the rooms and work areas must be such that hygienically clean areas and products within them are separate from unclean areas. As far as possible, product flow should be arranged so that no intersections occur. Ideally, incoming products, raw materials, storage, processing, packaging and dispatch should take place step by step from one end of the plant to another without products from different production stages intersecting one another. Water supply must be adequate and sufficient for processing and cleaning purpose. Water must be tested/ analyzed at least twice in a year in an approved laboratory for compliance with drinking water standard. Toilet rooms must not have direct access to processing area and sufficient for personal use. Toilets walls and floors should be made light colored preferably tiled. Operations are separated as necessary. There are clear advantages in minimizing the number of interior walls since this simplifies the movement of materials and employees, simplified supervision, and reduces the area of wall that needs cleaning and maintenance.

Equipment’s/Machines for Agro-Processing Centre: While selection of APC equipment’s, some other considerations are product to be prepare, raw material availability, capacity of machine, power source, ease in operation, safety in operation, material of manufacturing (It should be of food grade), manpower requirement and ease in repair and maintenance should also be considered. The equipment’s will be selected on the basis of food and other commodities prioritized for the area of establishment of APC.

- Cleaner Grader

- Washer cum Peeling Machine

- Mini dal mill

- Flour Mill

- (Stone less)

- Compact mini rice mill

- Pulverizer

- Oil Expeller

- Tray Dryer

- Hand sealer machine table top model (cat. No. 1012-A)

- Hand operated stitching machine (Cat. No. 0580)

- Grain moisture meter

- Weighing Balance

- Storage racks

- Material handling tables

- Plastic crates

- Dust Collector

APC can implement different marketing strategy, such as, it can encourage local producers to bring their raw materials for processing and charge for the facilities provided and also APC can procure raw materials from economically permissible areas, processes it, package it in proper packaging material and then sell it with a specific brand name. The APC entrepreneur should give more margins to the seller/vendor per unit product sold than others for enhancing the market of the products. The small-scale food processing sector is however under increasing threat and competition from large manufacturers who, does economics of scale and better presentation and marketing, can put small entrepreneurs’ out of business. The powerful large-scale food sector is also often able to influence government and international policies and laws and so prevent the small manufacturer from entering production or selling in a particular market. The pleasant appearance, presentation and advertising strategy should be used to sell the produce. Good packaging is the heart of presentation, marketing and thus customer appeal. Agro-Processing Centre is an area of vital importance for small and medium food manufacturers if they are going to continue to compete and expand.

Points to be keep in mind for successful marketing:

- Product: What are you selling? What is the uniqueness of your product? What you offer different from your competitors and what benefits does it provide your customer?

- Price: What will it cost to get your product or service? How does it compare to your competitors? What will your profit margin be by selling at that price?

- Place: Where will your products and services be available for purchase? Where to sell your product?

- Promotion: How are you going to let the market know about your product or services? How will you tell them about the features and benefits you provide to entice them to check out what you offer?

- Include information about any incentives or coupons you'll use to attract business.

- People: Important if other people are involved in helping you create or deliver your product or service. Who are these people (i.e. sales people, virtual assistants) and what do they do

Agro-Processing Centre can play an important role in not only providing the employment and income to the farmers and rural people but also reducing the post-harvest losses of agricultural produce. Strong linkages will be establish between farmers and consumers which is most important factor faced by the agriculturist while marketing the fresh and processed products. It will help the people to reduce the share of middle man and hence to get more profit from direct marketing. This will not only generate income to APC owner/entrepreneur but also trigger development process in terms of improved agricultural practices for sustainability and food surplus. APC would also provide the opportunity for investment in rural area and in establishing the infrastructure support for the agricultural produces. Establishment of APC is a probable solution for farmers and strengthening agriculture by making it more profitable and productive to rural unemployed youth.

About Author / Additional Info: