Authors: Chandan Solanki1, Dhritiman Saha1 and Pankaj Kumar1

1 ICAR-CIPHET, Ludhiana, Punjab, India 141 004

chandan4uu12@gmail.com

Introduction of Stainless Steel

“Stainless steel is the essential material from farm to table”. Stainless steel is primarily used when corrosion or oxidation are a problem. The function that they perform cannot be duplicated by other materials for their cost. Over 50 years ago, it was discovered that a minimum of 12% chromium would impart corrosion and oxidation resistance to steel. Hence, the definition “Stainless Steels”, are those ferrous alloys that contain a minimum of 12% chromium for corrosion resistance. This development was the start of a family of alloys which has enabled the advancement and growth of food processing, chemical processing and power generating systems upon which our technological society is based. Subsequently several important sub-categories of stainless steels have been developed. These sub-categories are austenitic, martensitic, ferritic, duplex, precipitation hardening and super alloys.

Grades & types

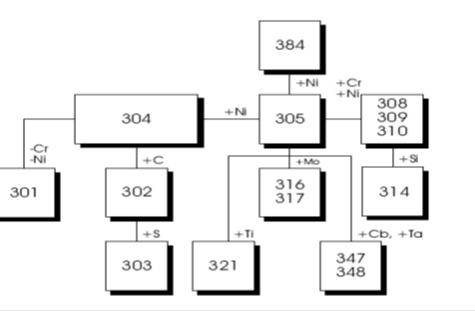

- Austenitic Grades

- The austenitic grades are not magnetic.

- The most common austenitic alloys are non-chromium-nickel steels and are widely known as the 300 series.

- The austenitic stainless steels, because of their high chromium and nickel content, are the most corrosion resistant of the stainless group providing unusually fine mechanical properties.

- They cannot be hardened by heat treatment, but can be hardened significantly by cold-working.

Fig. 1. Austenitic group of stainless steel

Straight Grades

The straight grades of austenitic stainless steel contain a maximum of .08% carbon. As long as the material meets the physical requirements of straight grade, there is no minimum carbon requirement.

“L” Grades

The “L” grades are used to provide extra corrosion resistance after welding. The letter “L” after a stainless steel type indicates low carbon (as in 304L). The carbon is kept to.03% or under to avoid carbide precipitation. Carbon in steel when heated to temperatures in what is called the critical range (800 degrees F to 1600 degrees F) precipitates out, combines with the chromium and gathers on the grain boundaries. This deprives the steel of the chromium in solution and promotes corrosion adjacent to the grain boundaries. By controlling the amount of carbon, this is minimized. For weld ability, the “L” grades are used. You may ask why all stainless steels are not produced as “L” grades. There are a couple of reasons. First, the “L” grades are more expensive. In addition, carbon, at high temperatures imparts great physical strength. Frequently the mills are buying their raw material in “L” grades, but specifying the physical properties of the straight grade to retain straight grade strength. A case of having your cake and heating it too. This results in the material being dual certified 304/304L; 316/316L, etc.

“H” Grades

The “H” grades contain a minimum of .04% carbon and a maximum of .10% carbon and are designated by the letter “H” after the alloy. People ask for “H” grades primarily when the material will be used at extreme temperatures as the higher carbon helps the material retain strength at extreme temperatures. You may hear the phrase “solution annealing”. This means only that the carbides which may have precipitated (or moved) to the grain boundaries are put back into solution (dispersed) into the matrix of the metal by the annealing process. “L” grades are used where annealing after welding is impractical, such as in the field where pipe and fittings are being welded.

Type 304

The most common of austenitic grades, containing approximately 18% chromium and 8% nickel. It is used for chemical processing equipment, for food, dairy, and beverage industries for heat exchangers, and for the milder chemicals.

Type 316

Contains 16% to 18% chromium and 11% to 14% nickel. It also has molybdenum added to the nickel and chrome of the 304. The molybdenum is used to control pit type attack. Type 316 is used in chemical processing, the pulp and paper industry, for food and beverage processing and dispensing and in the more corrosive environments. The molybdenum must be a minimum of 2%.

Type 317

Contains a higher percentage of molybdenum than 316 for highly corrosive environments. It must have a minimum of 3% “moly”. It is often used in stacks which contain scrubbers.

Type 317L

Restricts maximum carbon content to 0.030% max. and silicon to 0.75% max. for extra corrosion resistance.

Type 317LM

Requires molybdenum content of 4.00% min.

Type 317LMN

Requires molybdenum content of 4.00% min. and nitrogen of .15% min.

Type 321, Type 347

These types have been developed for corrosive resistance for repeated intermittent exposure to temperature above 800 degrees F. Type 321 is made by the addition of titanium and Type 347 is made by the addition of tantalum/columbium. These grades are primarily used in the aircraft industry.

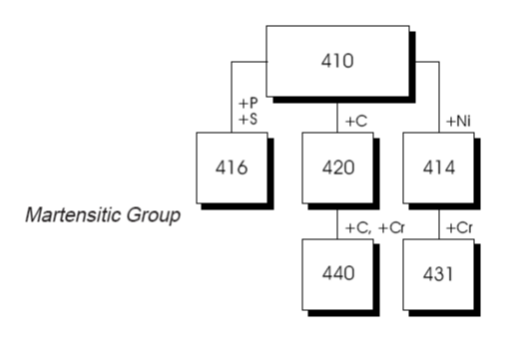

- Martensitic Grades

1. Martensitic grades were developed in order to provide a group of stainless alloys that would be corrosion resistant and hard enable by heat treating.

2. The martensitic grades are straight chromium steels containing no nickel.

3. They are magnetic and can be hardened by heat treating.

4. The martensitic grades are mainly used where hardness, strength, and wear resistance are required.

Fig. 2. Martensitic Group

Type 410

Basic martensitic grade, containing the lowest alloy content of the three basic stainless steels (304, 430, and 410). Low cost, general purpose, heat treatable stainless steel. Used widely where corrosion is not severe (air, water, some chemicals, and food acids. Typical applications include highly stressed parts needing the combination of strength and corrosion resistance such as fasteners.

Type 410S

Contains lower carbon than Type 410, offers improved weld ability but lower hardenability. Type 410S is a general purpose corrosion and heat resisting chromium steel recommended for corrosion resisting applications.

Type 414

Has nickel added (2%) for improved corrosion resistance. Typical applications include springs and cutlery.

Type 416

Contains added phosphorus and sulphur for improved machinability. Typical applications include screw machine parts.

Type 420

Contains increased carbon to improve mechanical properties. Typical applications include surgical instruments.

Type 431

Contains increased chromium for greater corrosion resistance and good mechanical properties. Typical applications include high strength parts such as valves and pumps.

Type 440

Further increases chromium and carbon to improve toughness and corrosion resistance. Typical applications include instruments.

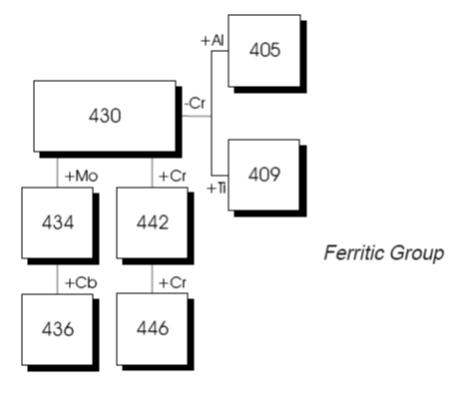

- Ferritic Grades

Fig. 3. Ferritic Group

Type 430

The basic ferritic grade, with a little less corrosion resistance than Type 304. This type combines high resistance to such corrosives as nitric acid, sulphur gases, and many organic and food acids.

Type 405

Has lower chromium and added aluminium to prevent hardening when cooled from high temperatures. Typical applications include heat exchangers.

Type 409

Contains the lowest chromium content of all stainless steels and is also the least expensive. Originally designed for muffler stock and also used for exterior parts in non-critical corrosive environments.

Type 434

Has molybdenum added for improved corrosion resistance? Typical applications include automotive trim and fasteners.

Type 436

Type 436 has columbium added for corrosion and heat resistance. Typical applications include deep-drawn parts.

Type 442

Has increased chromium to improve scaling resistance. Typical applications include furnace and heater parts.

Type 446

Contains even more chromium added to further improve corrosion and scaling resistance at high temperatures. Especially good for oxidation resistance in sulphuric atmospheres.

- Duplex Grades

- Precipitation Hardening Grades

- Super alloy Grades

Disadvantages of stainless steel

High initial cost.

Difficult to fabricate, or in other words, it is not as malleable as other metals, say iron, and hence if not fabricated properly, results in costly re-work.

Difficult to weld.

High cost of polishing etc. i.e. adding finishing touches for the market.

Advantages of stainless steel

Easy to clean and maintain: Stainless steel does not absorb dirt; in fact, it actually resists smudges, fingerprints and scuff marks relatively easily, making it very easy to clean and maintain. Stainless steel appliances can be wiped down with a damp cloth and sanitized easily. The surface can be protected with a cleaner to preserve its smooth, sleek and shiny surface.

Long life span: Stainless steel does not fade or become discoloured over time. It's also a rust-proof and stain-resistant material, so it will maintain its shine and preserve all of the aesthetic qualities of your appliances for several years to come.

Does not harbor germs: Because stainless steel is non-porous, it resists bacteria and germs more effectively than wood or plastic surfaces. Stainless steel can be wiped clean with a disinfectant cleaner after use, and is an attractive option for homes with young children and pets or for anyone who wants to keep their kitchen as clean and immaculate as possible.

Aesthetically pleasing: Stainless steel appliances can complement almost any kitchen or home design and theme, and the sleek, gleaming metallic finish can be balanced out with wood or plastic accents. Stainless steel is aesthetically pleasing and can be used as a surface material on a variety of appliances, including dishwashers, washers, dryers, countertops, refrigerators, freezers and stove tops.

Does not affect flavor of foods: Stainless steel is one of the most hygienic surfaces available, so any foods that come into contact with the surface or material do not attract dirt or germs. Stainless steel also does not react with any foods that may be used during meal preparation and cooking

Stainless Steel in the Dairy Industry (A Sustainable Solution for Human Diet)

Why Stainless Steel?

The development of stainless steel in the food industry is explained by the fact that it corresponds exactly to the requirements expected of materials in contact with food. The requirements fall into one of the following three categories:

- Chemical, bacteriological and organoleptic neutrality with regard to the food product.

- Ability to be cleaned so the hygiene and appearance of the product is guaranteed.

- Durability, including resistance to corrosion and aging.

Segmentation of the dairy market which stainless steel?

The equipment required to manufacture various dairy products includes:

- Farm equipment (including milking equipment, barns and sheds, milk tanks).

- Road tankers.

- Vats (such as storage tanks, maturation tanks, process tanks with agitators).

- Heat treatment equipment for pasteurisation or sterilisation (for example, plate exchangers, tubular coolers, evaporators).

- Specific equipment for making dairy products such as cheese and butter (for example, curd slicer, churns, butyrate machines).

- Other equipment (such as packaging lines, pumps, valves).

Cleaning of stainless steel equipment

Effective cleaning is essential in maintaining the integrity of the process and in prevention of corrosion. The choice of cleaning method and the frequency of its application depends on the nature of the process, the food being processed, the deposits formed, and hygiene requirements etc. The cleaning methods listed are suitable for stainless steel equipment.

- Water and Steam

- Mechanical Scrubbing

- Scouring Powder and Detergents

- Alkaline Solutions

- Organic Solvents

- Nitric Acid

Chemical disinfectants are often more corrosive than cleaning agents and care must be exercised in their use.

Hypochlorites -

Hypochlorites, chloramine and other disinfectants can liberate free chlorine, which can cause pitting. Sodium hypochlorite or potassium hypochlorites are often used in commercial sterilising agents. If these substances are used with stainless steel, the duration of the treatment should be kept to minimum and followed by thorough rinsing with water.

At higher temperatures, chloride-containing sterilising agents should not be used with stainless steel. Milton solutions (hypochlorite & chloride) can be very aggressive to stainless steels.

Tetravalent ammonium salts: Tetravalent ammonium salts are much less corrosive than hypochlorites, even when halogens are present in their formulation.

Iodine Compounds: Iodine compounds may be used for the disinfection of stainless steel.

Nitric acid: Even at low concentrations, nitric acid has a strong bactericidal action and can be a low cost disinfectant for stainless steel equipment, especially in dairies and pasteurising equipment.

Maintenance of food process equipment

Stainless steel equipment often contains gaskets or other components that can absorb or retain fluids. These liquids may be become concentrated by evaporation and corrosion may ensue. Equipment should be disassembled occasionally for thorough cleaning. If the disassembled equipment exhibits corrosion (crevice corrosion usually), then the corroded surfaces should be cleaned.

Typical applications of the various stainless steel types

| Types | Typical Applications |

| 420 (martensitic) | Cooks and professional knives, spatulas etc |

| 430 (ferritic) | Table surfaces, equipment cladding, panel (ie components requiring little formability or weldability). Used for moderately corrosive environments (e.g. vegetables, fruits, drinks, dry foods, etc). |

| 304 (austenitic) | Vats, bowls, pipework, machinery parts (i.e. components requiring some formability or weldability). Corrosion resistance superior to 430. |

| 316 (austenitic) | Components used with more corrosive foods (e.g. meat/blood, foods with moderate salt contents), which are frequently cleaned, with no stationary solids and not under excessive stress. |

| 1.4539 (austenitic) | Used with corrosive foods (e.g. hot brine with solids that act as crevice forms, stagnant and slow moving salty foods). |

| 1.4462 (duplex) | Used with corrosive foods (e.g. hot brine with solids, stagnant and slow moving salty foods). Higher strength than austenitics. Good resistance to stress corrosion cracking in salt solutions at elevated temperatures. |

| 6%Mo. types (austenitic) | Used with corrosive foods (e.g. hot brine with solids, which act as crevice formers, stagnant and slow moving salty foods). Good resistance to stress corrosion cracking in salt solutions at elevated temperatures. Used in steam heating and hot work circuits, hot water boilers, etc |

References:

1) www.worldstainless.org

2) http://www.sppusa.

3) www.worldstainless.org

4) Overstock.com.htm

About Author / Additional Info:

I am working as a scientist at ICAR-CIPHET, Ludhiana (ISO 9001:2015 institute since last 4 years. Our team work mainly focus on the post-harvest handling of food grains and oilseed &, value addition and preservation of food commodity.

I am also working in the area of microwave processing in food applications at IAR-CIPHET, Ludhiana.